- Home

- About Us

- Network

- Catalogue

- Products

Agriculture Machinery

Pump Sets

Centrifugal Pumps

CD / DV Belt Driven Centre Delivery, Single ( Vee or Flat ) Pulley type.

CD / DV Belt Driven Centre Delivery, Single ( Vee or Flat ) Pulley type. SD / SDLF Belt Driven , Side Delivery, Single ( Vee/Flat) Pulley or Loose Fast ( Double ) Pulley.

SD / SDLF Belt Driven , Side Delivery, Single ( Vee/Flat) Pulley or Loose Fast ( Double ) Pulley. Portable type for High Speed Engine Direct Couple, Centre Delivery, Volute Casing Type.

Portable type for High Speed Engine Direct Couple, Centre Delivery, Volute Casing Type. Direct Couple, Centre Delivery, Volute Casing Type.

Direct Couple, Centre Delivery, Volute Casing Type.

Diesel Welding Generator

Alternator (A.C. Generators)

- Quality

- Blog

- Contact us

Genrating Sets

Power Genset / Welding Sets

- Home

- Genrating Sets

AGRO / FARM MACHINERY

- Agriculture Machinery

Maize Sheller Cum Husk Remover (Corn Shelling Machines)

Maize Sheller Cum Husk Remover (Corn Shelling Machines) Hammer Mill, Hullers and Chaff cutter

Hammer Mill, Hullers and Chaff cutter Multi Crop Thresher Motor/ Engine Operated

Multi Crop Thresher Motor/ Engine Operated Multi Crop Thresher Tractor Operated

Multi Crop Thresher Tractor Operated Seed Drill Cum Fertilizer Drill Tractor Operated, Planter

Seed Drill Cum Fertilizer Drill Tractor Operated, Planter Seed Drill Cow Bullock Driven

Seed Drill Cow Bullock Driven Paddy Threshers Tractor/Motor/Engine driven

Paddy Threshers Tractor/Motor/Engine driven Maize / Corn Mill and Huller

Maize / Corn Mill and Huller Rotostar Grain Separator

Rotostar Grain Separator Indended Cylinder Grader

Indended Cylinder Grader Farming Equipment / Machinery

Farming Equipment / Machinery Cream Separators, Processing Machines for Dairy Industries

Cream Separators, Processing Machines for Dairy Industries

IRRIGATION / DEWATERING

- Pump Sets

Diesel Operated, With Petter/Lister Indian style Engine

Diesel Operated, With Petter/Lister Indian style Engine Pumpset with Double Cylinder Engine with High Head Pump (Heavy Duty)

Pumpset with Double Cylinder Engine with High Head Pump (Heavy Duty) Syria type Pumpset 7.5 H.P. Air cooled engine with 4*4 inch Split Casing type Pump

Syria type Pumpset 7.5 H.P. Air cooled engine with 4*4 inch Split Casing type Pump Heavy Duty CI Casting Coulping 52 Pumpset can be stuffed in one 20 FT Container

Heavy Duty CI Casting Coulping 52 Pumpset can be stuffed in one 20 FT Container Indian type Pumpset Oil Seal Pump eith 8 H.P Water Cooled Engine with Big Wheels

Indian type Pumpset Oil Seal Pump eith 8 H.P Water Cooled Engine with Big Wheels Lister type Pumpset Nigeria type

Lister type Pumpset Nigeria type Pumps With Gear for Tractor (PTO operated) with rain gun

Pumps With Gear for Tractor (PTO operated) with rain gun

- Centrifugal Pumps

CD / DV Belt Driven Centre Delivery, Single ( Vee or Flat ) Pulley type.

CD / DV Belt Driven Centre Delivery, Single ( Vee or Flat ) Pulley type. SD / SDLF Belt Driven , Side Delivery, Single ( Vee/Flat) Pulley or Loose Fast ( Double ) Pulley.

SD / SDLF Belt Driven , Side Delivery, Single ( Vee/Flat) Pulley or Loose Fast ( Double ) Pulley. Portable type for High Speed Engine Direct Couple, Centre Delivery, Volute Casing Type.

Portable type for High Speed Engine Direct Couple, Centre Delivery, Volute Casing Type. Direct Couple, Centre Delivery, Volute Casing Type.

Direct Couple, Centre Delivery, Volute Casing Type.

POWER GENSET WELDING SETS

AGRO ENGINE / PRIME MOVER

- Diesel Engine

Water Cooled

Water Cooled Air Cooled

Air Cooled Lister Type

Lister Type Mini Light Weight Diesel Engine

Mini Light Weight Diesel Engine “Badshah” Water Cooled 15 HP, 2 in 1 Diesel Engine

“Badshah” Water Cooled 15 HP, 2 in 1 Diesel Engine 3 Cylinder Petter Type Diesel Engine

3 Cylinder Petter Type Diesel Engine SAE 3, 11.5 Inch Bell Housing Diesel Engines

SAE 3, 11.5 Inch Bell Housing Diesel Engines P.T.O Clutch Type (Mechanical On /Off) Diesel Engines

P.T.O Clutch Type (Mechanical On /Off) Diesel Engines Marine Diesel Engines with Gear Box.

Marine Diesel Engines with Gear Box. Protected: Price List

Protected: Price List

Spare Parts

DC Generators / DC Alternator

DC Alternator, Generator

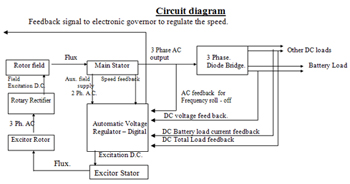

The conventional method to have auxiliary DC Supply for battery charging & other DC Loads is to use a diesel generating set of constant speed & a rectifier unit.Integrated Electric developed a variable speed DC Alternator for coupling with Diesel engine as a source of DC auxiliary power. The principle of working is as under. The basic generator will be just like any brushless AC Generator consisting of main stator, Main rotor, Exciter stator & Exciter rotor. The generator is of three phase, variable speed, variable kW output

For. Example the DC Alternator is capable of delivering :

- 2 kW at 750 RPM

- 4 kW at 1500 RPM

- 8 kW at 3000 RPM

SYSTEM FEATURES

- The DC Alternator delivers constant DC Voltage at the terminals up to its rated load battery current or total full load & subsequently the voltage drops depending upon load & hence protect the Engine, Alternator & the load.

- User settable DC Output voltage, DC Battery current & DC Overall current

- The control panel gives signal to electronic governor of the engine to operate at sub-synchronous (settable) and super synchronous speeds (settable) to get optimum fuel consumption & hence increase efficiency of the system & further increases the life of the engine

- Ripple will be less than 100 mV with battery & less than 300 mV with out battery

DC Alternator, Generator

PRINCIPLE OF OPERATION OF DC ALTERNATORS

I. The rotor of the revolving field generates a rotating flux which induces the following emf’s in the stator. The alternator builds up voltage with the help of residual magnetism & mainly from the permanent magnets housed in the exciter stator..

- 3 Ph. AC from the main armature windings.

- 2 Ph. AC from the auxiliary winding.

II. The 3 Ph.AC from the main stator is fed to the Diode bridge.

III. The automatic Digital voltage regulator (AVR) receives the following signals.

- DC Output voltage.

- 2 phase AC from the auxiliary winding.

- Speed feedback for frequency roll off

- DC Battery Current feedback.

- DC Total current feedback

DC Alternator, Generator

The AVR uses these signals to compute the amount of excitation required to maintain the terminal voltage up to its rated current rating & reduce the terminal voltage on further loading of DC Alternator & hence protect the DC Alternator from over loading. The digital AVR also monitors the total overall load current & gives feed back signal to electronic governor to change the speed depending on load.

I. The rotor of the revolving field generates a rotating flux which induces the following emf’s in the stator. The alternator builds up voltage with the help of residual magnetism & mainly from the permanent magnets housed in the exciter stator..

IV. The Exciter field induces 3 phase AC at 100Hz. in the exciter rotor.

V. The rotating diodes mounted in the exciter rotor rectify the AC voltage to DC Voltage and supply it to the Main rotor field winding

VI. This regeneration continues and till the rated DC output voltage is achieved. The output voltage will be maintained at its rated value up to its rated current as indicated on the name plate of the DC Alternator.

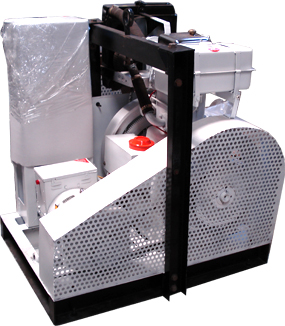

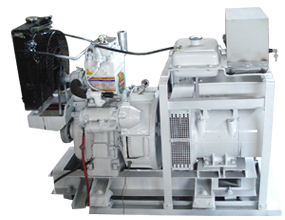

VIDHATA DC GENERATOR

VIDHATA DC

Generator using its bush less / AVR Alternator technology in 2008. Since then numerous organizations have performed extensive testing on our generators VIDHATA assembles the genset to meet its’ clients requirements by adding the appropriate diesel engine to our DC alternators. The engines are available in either a liquid or air-cooled version. VIDHATA has designed this DC alternator incorporating state-of-the-art technologies and all new tooling to meet the increased performance demand for.

- Low Maintenance

- Low EMI Emissions

- Very High Quality Electrical Output

- Light Weight

- Low Fuel Consumption

- Low Acoustic Noise

- High and Low Ambient Operation (-40° to 125° F)

VIDHATA

Power has met these performance goals through an integrated engineering effort involving detailed analysis of engine, voltage regulator, field coil, magnet, stator, rotor system’s output voltage and current.

SPECIFICATIONS

- DC output 12 volts, 200 Amps

- DC Voltage regulated at 1 Volt from no-load to full load

- Dc Voltage will reduce drastically after the load current reaches its rated current & hence protecting generator & Engine from over load

- Seperately Excited, Brushless, Provided with class ‘H’ Insulation, Temp. rise limited to Class F. Suitable for an ambient temperature of 40C

- D.C. Alternator for recharging battery banks. This is not an automotive style alternator because of their poor efficiency

- 200 amps DC for recharging battery banks, DC generator is the most efficient and least cost solution

- Require 5 h.p Prime mover at 1500 RPM ENGINE suitable to make a DC generator

- We can supply complete DC generator close coupled or coupling type both with water cooled and air cooled engines

LOW MAINTENANCE AND HIGH RELIABILITY

- The unique alternator design allows us to turn the engine at low speeds, thereby extending engine life.

- The voltage regulator has automatic governing at high electrical load demands the regulator automatically increases engine RPM; at low loads the engine speed is automatically decreased.

- VIDHATA Power’s alternator has no: brushes, slip rings, There are no alternator parts to wear.

- There are no electronic parts (diodes, etc.) nor electrical connections inside the alternator. There is nothing to short or vibrate loose inside the alternator.

- The alternator is almost impossible to damage electrically. The outputs can be shorted for minutes without damage.

- The output current is monitored by the voltage regulator through a current transducer. The voltage regulator has an adjustable current limit on the output. It is virtually impossible to overload the alternator.

- VIDHATA Power’s alternator should have an life of exceeding 50000 hours

- The engine is protected against: over-temperature, low oil pressure, over-speed, (OPTIONAL).

- The alternator’s rotor is dynamically balanced to improve the engine’s bearing life.

LOW FUEL CONSUMPTION

The VIDHATA alternator has an efficiency of between 75 to 85% versus 55 to 70% for other DC alternators. Consume only 700 gm diesel in 1 hr.

HIGH AND LOW AMBIENT OPERATION

- During starting the regulator keeps the field current off. This feature coupled with the small light weight rotor provides a minimal load on the starter motor.

- For low ambient temperatures (-40° to 10° F) cold starting aids are available.

- The higher alternator efficiency allows the engine to run cooler in high ambient temperatures. The increased alternator efficiency reduces the mechanical load on the engine which then reduces the engines cooling requirement.

OPTIONS

ENGINE STYLES

- Diesel Engine: either air-cooled or water-cooled.

VIDHATA DC GENERATORS ARE MORE EXPENSIVE TO PURCHASE THAN AC GENERATORS BECAUSE

- Our alternators uses a high frequency design (360Hz) that reduces weight, size, and greatly improves the quality of electrical power. The high frequency design requires more labor to wind the stator. Typical AC generators are only 50 or 60 Hz.

- The stator has a 6-phase design to also improve electrical quality and the torque ripple on the engine for better fuel economy. The 6-phase design requires more labor to wind the stator. Standard AC generators are only single or three phase.

- The VIDHATA’s DC generator set is optimized to produce a high current, low voltage power output for charging batteries and powering DC loads directly. The AC generator is optimized for a high voltage, low current output and requires an external power supply or battery charger to convert AC into DC. The low voltage, heavy current windings are more expensive to wind.

- VIDHATA’s DC generator is very corrosion resistant. We make extensive use of stainless steel fasteners and coated aluminum materials. Certain components must be constructed of steel due the magnetic properties; here we coat with high temperature coatings and/or Cadmium (CAD) plating. Corrosion resistance is important for installations in marine or humid environments or exposed to agricultural and garden chemicals. This construction is not typical of AC generators.

- VIDHATA uses the very best magnetic wire in an HML grade for a class H rating. This facilitates long life in warm or dusty climates.

Why use DC Generators for Telecommunications, Solar, UPS, Backup, Prime Power.There is not a single universal reason why all applications should choose a DC generator over an AC generator. There are, however, specific reasons for each project or a combination of reasons that favor the DC generator. Some of which include.

APPLICATIONS IN GENERAL (INCLUDING SOLAR/WIND HYBRID, PRIME POWER, AND BACKUP)

- The DC generator system is designed and optimized to deliver the high currents at low voltages required for battery charging and operating DC loads. No battery chargers or power supplies are required.

- DC generators do not require a transfer switch. Transfer switches lower system reliability.

- In prime power applications the DC generator lowers the overall cost of the system.

- Certain AC generators and switch mode power supplies are incompatible. These AC generators have voltage regulators that cannot regulate voltage due to the current pulsing load of the switch mode power supplies. VIDHATA DC generators when connected to a battery do not suffer this incompatibility.

- DC generators are more fuel-efficient. Site operators want the longest run time with the least amount of fuel on site.

- VIDHATA’s DC generators are simpler in design, have considerably less maintenance and are more reliable than AC generators. Propane carburetion and electronic speed governors require frequent calibration and testing. If the propane carburetion, ignition system, or governor speed control should develop a problem, alternator voltage regulation and frequency control will fail. Some equipment powered by the generator will be damaged, other equipment may survive. How many of your AC loads can tolerate a wide swing in frequency?.

- VIDHATA’s DC generators have a current limit control to prevent the alternator from overheating and the engine from stalling during shorts or overloads. This feature is extremely important in battery charging because a battery in a low state of charge can demand more power than the generator or battery charger can manage. VIDHATA’s DC generators will continues to supply power under current limit control, allowing the battery to increase its charge and drop its current demand. The AC generator uses a fuse or circuit breaker to protect against shorts and over current so the battery fails to get charged if it is overly discharged. The additional problem is that for remote sites a person is required to visit the site to replace or reset the fuse or circuit breaker and devise a means where the batteries can be brought to a state of charge where the batteries can take over.

- VIDHATA DC generators can be connected in parallel and load share. Paralleling these small AC generators is not practical. In many projects there are concerns about future site expansion and given load estimates are sometimes understated.

- Maintainability. DC generators use smaller engines that can be lifted by hand and transported to a shop for repair. The high-level generator mechanics are not required, or their expensive travel time to the site.

- AC generators are typically oversized to handle starting currents of motors and to provide light enough engine loads to facilitate speed regulation. Engines that are lightly loaded build up carbon around the valves and exhaust lines (wet stacking) this creates additional engine maintenance.

- DC generators are considerably smaller in size and use smaller horsepower engines. This facilitates both roof mount installations and installations inside the small shelters, as well as the required permit process.

- DC generator lowers the costs to install and operate. It is smaller in size and requires less site support. Transport to the site and installation is facilitated because: smaller shelter and concrete pads can be used, elevator transport to roof rather than crane, smaller helicopters or vehicles for transport. Fuel consumption is lower, so cost to transport fuel to the site is lower (transportation of the fuel to the site can be very expensive).

- Engines need a warm up period before they are able to provide full power, for an AC generator this translates to providing a stable frequency and voltage. VIDHATA s DC generator can deliver power at a reduced level immediately after starting, then switch to full power after warn up. Also a cold engine can exhibit speed fluctuations, which has no effect on VIDHATA ’s DC generators.

UPS SYSTEMS

- VIDHATA s DC generators connect direct to the battery bank so there are fewer problems with on site permitting. Many inspectors and utilities are concerned with isolation of the AC generator from the utility grid. Using a DC generator there should be no questions on isolation from the inspectors.

- VIDHATA s DC generator can provide regulated charging to the battery and is unaffected by the pulse currents of the switch mode inverter.

COMPARISON CHART FOR TELECOMMUNICATIONS APPLICATIONS

| NO MATTER WHICH WAY YOU LOOK AT IT, DC SETS ARE SUPERIOR! | |

| Creator gensets from country | AC GENSET |

| For N+1 redundancy, peak load demand, and site expansion, multiple DC generators can be operated at the same time and power outputs can be paralleled. | It is impractical to parallel AC generators for these applications; therefore they must be over-sized for peak load demands and future expansion. Small loads can cause the engine to “wet stack”. |

| DC generator backs up both utility power and the rectifier bank. | rectifier bank. AC generators back up only utility power. If the rectifier fails, the site is down. |

| Backing up power board reduces N+1 redundancy demand on the number of rectifier modules. This lowers the purchase and operational costs. | N+1 redundancy of rectifier modules within a power board increases site capital and operating cost. |

| The battery charger or rectifier and the transfer switch for both prime power and solar hybrid applications can be eliminated. Fuel consumption is reduced, and reliability is greatly increased. | Rectifiers, transfer switch and controls add considerably to the purchase, installation, and maintenance costs. |

| Variable engine speed option automatically adjusts to meet battery charging and load requirements, providing up to 40% savings in fuel. Engine speeds can vary without affecting voltage regulation. | Engine must run at fixed speeds in order to maintain 60 or 50Hz frequency. Engine speed control provisions add to maintenance and reliability problems. Running engine without load shortens engine life. |

| Continuously running the DC generator during long power outages can be avoided in order to conserve fuel and reduce maintenance. The generator can charge the battery, then shut down and begin cycle again. | The cumbersome design of an AC Generator/ transfer switch/rectifier system make frequent cycling undesirable. |

| With VIDHATA ’s high efficiency alternator we are able to use smaller horsepower engines, which produce lower acoustic noise. Smaller engines also facilitate installation permits on sites where the regulations are based on horsepower and noise. | Combined with the rectifier power losses and the rectifier and air conditioning current surges during startup, the engines and alternators on the AC sets require over sizing. Engines are also oversized to assist in output frequency regulation. |

| A DC generator can “come on line faster than an AC generator. This allows a reduction in the size of the battery bank. Reducing the battery bank size lowers procurement and replacement costs. | From experience, larger battery banks are required for AC generator backup systems. |